زوج من الكابلات Atlas Equator Achromatic 2 RCA to 2 RCA من اتلاس - 1 م

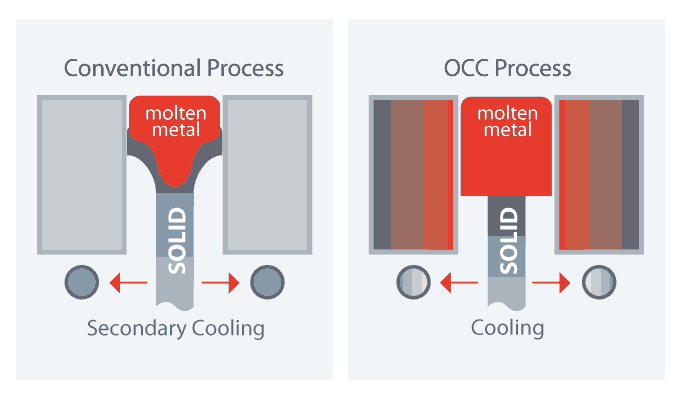

تستخدم Atlas فقط أنقى أنواع النحاس في منتجاتها مع كون خط الاستواء اللوني ليس استثناءً. باستخدام تقنية Atlas 'Ohno Continuous Cast (OCC) 5N (نقاوة 99.999٪ - أعلى درجة نقاء متوفرة) ، يتم "سحب" كل حبلا من بلورة نحاسية واحدة ، مما يتيح تدفق الإشارات الكهربائية بأقل عدد من عمليات الحذف. تصميم محوري ، يستخدم Equator Achromatic 60 حاملًا من النحاس OCC لإنشاء موصل الإشارة الخاص به ، والذي يتم وضعه في PEF (البولي إيثيلين الرغوي) الرغوي بالغاز ، والذي يوفر عازلًا أكثر خاملًا وثباتًا. تم تجهيز خط الاستواء اللوني بمقابس أطلس Achromatic RCA. يتميز موصل Integra منخفض الكتلة باتصال لحام بارد خالٍ من اللحام ، محسّن لإنشاء مسار إشارة متماسك ومستمر. يتميز كل قابس Achromatic بأقواس مترافقة مطلية بالذهب ، والتي تفتح عند الإدخال وتمسح مسار الإشارة نظيفًا. للحفاظ على مسار إشارة نظيف ، ما عليك سوى إزالتها وإعادة إدخالها بشكل دوري.

الميزات:

- سدادات RCA اللونية

- موصلات OCC

- عازل PEF

- انشاء Co-ax

المنتجات المقترحة

منتجات شاهدها عملاء آخرون

معاينة موقع سماعة تك

تفاصيل المُنتج

- الانشاء: coax (مزدوج الشاشة)

- المواد: OcC

- عازل: PEF (رغوة PE)

- الشاشة: OFC ، 95٪ (جديلة مزدوجة من OFC)

- السعة: 53.27 بيكو فاراد / م

- محاثة: 0.40 µH / م

- المقاومة: 0.027 أوم / م

- المقاومة: 78.25 أوم عند (1 ميجا هرتز)

- القطر الخارجي: 8.5 مللي متر

ماذا في العلبة

- زوج من الكابلات Atlas Equator Achromatic 2 RCA to 2 RCA من اتلاس

الفيديوهات

مواصفات المُصنع

Achromatic Plugs

Atlas’s expert electro-mechanical knowledge has led to the innovation of the next generation of RCA plugs. Known as the ‘Atlas Achromatic RCA plug’, Atlas has focused on improving both performance and appearance to create a higher performance starting point for their RCA cables as well as eliminating variability in performance. This has been achieved by refocusing on materials and the assembly processes.

Atlas has made 4 key changes with the Achromatic RCA plug. Firstly, the barrel of the Achromatic plug features a high stability ABS material. This is strong, stable and of superlative surface quality.

There is also an improvement to the Achromatic plug’s contact geometry, aiding the contact properties of the plug and the self-cleaning wiping action to ensure contacts are in optimal condition and to maximise signal transmission.

The third change Atlas made was around the rifling of the RCA pin. This improvement self-aligns the conductors during the cold weld processing, ensuring a superior stable connection.

Finally, there is a reduction in the overall mass of the RCA plug by 8% which has shown to improve signal transmission.

The above changes mean a solder-free, low mass, self-cleaning, recyclable RCA plug with a non-conductive body.

OCC Copper

The Ohno continuous casting method re-heats the extrusion as the molten copper is forced out of the mould and very slowly and gradually draws the grain or crystal down the conductor''s length, creating a ‘single crystal structure.’ Actually, because no copper is 100% pure, there will always be a few boundaries produced by impurities. The frequency of boundaries created are quite insignificant. A typical crystal in a copper conductor drawn to 0.3 mm diam. using the OCC process is 125.00 metres long! The benefits are obvious, with almost no crystal boundaries, the audio signal is no longer impeded down the copper wire and more information and detail is delivered faithfully to the receiving equipment.

BHD

BHD JOD

JOD KWD

KWD LBP

LBP OMR

OMR SAR

SAR USD

USD AED

AED